Workplace safety should always be a top priority for any business or organization. There are many factors that contribute to safety, including proper training, equipment maintenance, and the use of specialized tools and materials. One such material is lock wire, which plays a crucial role in mitigating risk and ensuring workplace safety. In this article, we will explore the importance of lock wire and its various applications across different industries.

Understanding Lock Wire and Its Applications

Lock wire is a type of wire that is used to secure fasteners and prevent them from loosening due to vibration, temperature changes, or other factors. It is commonly used in aviation, automotive, and other industries where machinery and equipment must operate in challenging environments. By preventing fastener loosening, lock wire helps to ensure that machinery and equipment remain stable and reliable over extended periods of operation, preventing costly downtime and equipment failures.

What is Lock Wire?

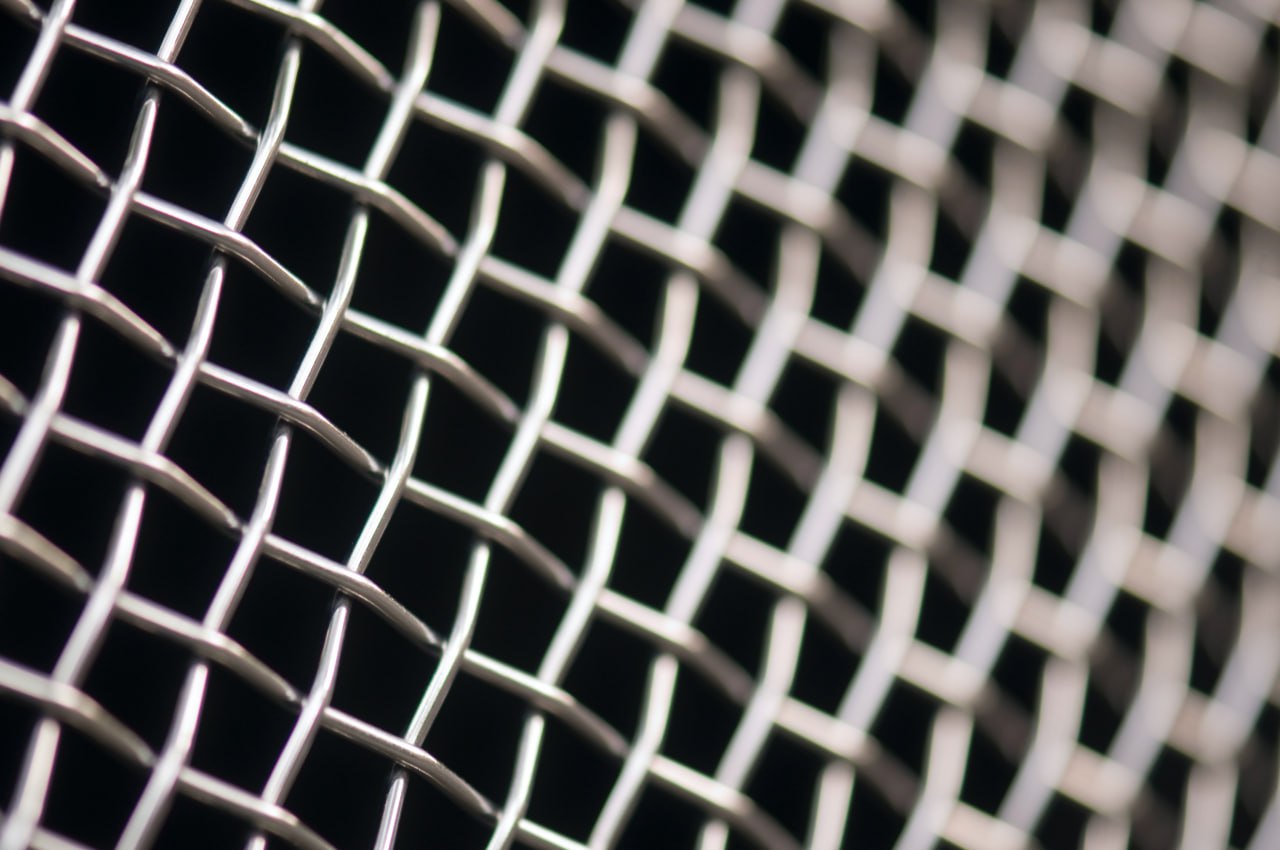

Lock wire is typically made from a high-strength material such as stainless steel or Inconel. It is usually available in gauges ranging from 0.020 inches to 0.080 inches, depending on the application. The wire is typically coated with a lubricant to make it more pliable and easier to work with.

Lock wire is also known as safety wire, and it is used to secure fasteners in a way that prevents them from loosening or falling out. This is achieved by twisting the wire around the fastener and then twisting it back on itself, creating a tight and secure fit that will not come undone under normal operating conditions.

Lock wire is an important component in many industries, and it is used to secure critical components such as bolts, nuts, and screws, as well as fluid lines, control cables, and other components. It is also used in high-performance racing applications where extreme conditions can cause loosening of traditional fasteners.

Common Uses of Lock Wire in Various Industries

Lock wire is used in a wide variety of industries, including aviation, automotive, construction, and manufacturing. In aviation, lock wire is used to secure critical components such as control cables, fuel lines, and other critical components. In the automotive industry, lock wire is used to secure components such as brake lines, suspension components, and other critical components. In construction, lock wire is used to secure scaffolding and other structures, while in manufacturing, it is used to secure machinery and other equipment.

Lock wire is also used in the marine industry, where it is used to secure components such as rigging and other critical components. In the military, lock wire is used to secure critical components on aircraft, vehicles, and other equipment.

Types of Lock Wire Materials and Their Properties

There are several materials that can be used for lock wire, including stainless steel, Inconel, and titanium. Stainless steel is the most common material due to its excellent corrosion resistance and high strength. Inconel is used in applications where high temperatures are present, such as in gas turbine engines. Titanium is a lightweight material that is often used in aerospace applications.

Stainless steel lock wire is available in several grades, including 302, 304, and 316. These grades offer varying levels of corrosion resistance and strength, making them suitable for a wide range of applications.

Inconel lock wire is a high-temperature material that is used in applications where temperatures can reach up to 2000°F. It is commonly used in gas turbine engines, where it is used to secure critical components such as blades and vanes.

Titanium lock wire is a lightweight material that is often used in aerospace applications. It is highly resistant to corrosion and has excellent strength-to-weight ratio, making it an ideal material for securing critical components in aircraft and spacecraft.

Overall, lock wire is an essential component in many industries, and its importance cannot be overstated. By securing critical components and preventing fastener loosening, lock wire helps to ensure that machinery and equipment remain stable and reliable over extended periods of operation, preventing costly downtime and equipment failures.

The Importance of Proper Lock Wire Installation

In industries such as aviation, aerospace, and automotive, proper installation of lock wire is crucial for ensuring safety and preventing equipment failure. Lock wire, also known as safety wire, is a type of wire that is used to secure fasteners such as bolts, nuts, and screws. It is called lock wire because it locks the fastener in place, preventing it from loosening due to vibration or other forces. In order for lock wire to function properly, it must be installed correctly. Proper installation involves several steps, including selecting the appropriate wire gauge and material, cleaning and preparing the fastener surfaces, and ensuring that the wire is wrapped tightly around the fastener to prevent movement. In the following sections, we will explore these steps in more detail.

Step-by-Step Guide to Installing Lock Wire

Installing lock wire may seem like a simple task, but it requires attention to detail and proper technique. The following are the general steps involved in installing lock wire:

- Select the appropriate wire gauge and material for the application. The wire gauge and material used for lock wire will depend on the size and type of fastener being secured, as well as the environment in which it will be used. Stainless steel wire is a common choice for lock wire due to its corrosion resistance and strength, but other materials such as titanium and Inconel may be used for specialized applications.

- Clean and prepare the surface of the fastener and surrounding components to remove any dirt, oil, or other contaminants. The surface of the fastener and surrounding components must be clean and free of any contaminants that could interfere with the wire’s ability to grip and hold the fastener. This can be done using solvents, degreasers, or other cleaning agents.

- Wrap the wire around the fastener at least two full turns, ensuring that the wire is tight and completely encircles the fastener. The wire should be wrapped tightly around the fastener, with each turn overlapping the previous one. The wire should completely encircle the fastener, with no gaps or spaces between the wire and the fastener.

- Twist the wire ends together using pliers, making sure that the twist is tight and secure. The wire ends should be twisted together tightly using pliers or other wire twisting tools. The twist should be tight enough to prevent the wire from unraveling or coming loose, but not so tight that it breaks the wire.

- Using diagonal cutters, trim the wire ends to within one-quarter inch of the twist. The wire ends should be trimmed using diagonal cutters or other wire cutting tools. The ends should be trimmed to within one-quarter inch of the twist, leaving enough wire to bend back against the fastener head in the next step.

- Bend the wire ends back against the fastener head to prevent snagging or injury. The wire ends should be bent back against the fastener head using pliers or other bending tools. This will prevent the wire ends from snagging on other components or causing injury to personnel.

Common Mistakes and How to Avoid Them

Improper installation of lock wire can lead to problems such as wire breakage, fastener loosening, and even equipment failure. Common mistakes to avoid include using the wrong wire gauge or material, failing to clean and prepare the surface properly, and wrapping the wire too loosely or unevenly. Ensuring that proper techniques are followed during installation can prevent these issues from arising. It is also important to inspect lock wire regularly for signs of wear or damage, and to replace it as needed.

Tools and Equipment for Efficient Lock Wire Installation

Proper installation of lock wire requires the use of specialized tools and equipment. These include pliers for twisting the wire and diagonal cutters for trimming the ends. Other tools that may be required depending on the application include wire strippers, locking pliers, and torque wrenches. Investing in high-quality tools and equipment can help to ensure that lock wire is installed efficiently and correctly. Additionally, proper training and certification in lock wire installation can help to ensure that personnel are knowledgeable and skilled in this important task.

Lock Wire’s Role in Preventing Equipment Failure

Lock wire plays a crucial role in preventing equipment failure by keeping fasteners secure and preventing movement due to vibration, temperature changes, or other factors. In this section, we will explore how lock wire works and its impact on equipment performance.

How Lock Wire Prevents Fastener Loosening

Lock wire works by creating tension between the fastener and its surrounding components, preventing movement and loosening over time. By wrapping the wire tightly around the fastener and its adjacent components, it creates a secure and stable connection that can withstand the stresses of operation. This helps to prevent fastener loosening and failure, as well as reducing the risk of damage to surrounding components.

The Impact of Vibration and Temperature on Fasteners

Vibration and temperature changes are two of the main factors that can cause fastener loosening and failure over time. As machinery and equipment operate, they generate significant vibration forces that can gradually loosen fasteners and cause equipment failure. Temperature changes can also cause fasteners to expand and contract, leading to loosening over time. Lock wire helps to mitigate these effects by preventing movement and loosening of fasteners, helping to ensure that equipment remains reliable and stable over time.

Case Studies: Lock Wire in Action

There are numerous examples of lock wire in action across various industries, including aviation, automotive, and construction. In aviation, lock wire is used extensively on critical components such as control cables, fluid lines, and engine components, where reliable performance is essential. In automotive racing, lock wire is used to secure critical fasteners on high-performance engines and suspension components, where vibration and other stresses can cause loosening. And in construction, lock wire is used to secure scaffolding and other structures where safety and stability are paramount.

Workplace Safety Benefits of Using Lock Wire

Beyond its impact on equipment reliability and performance, lock wire provides significant workplace safety benefits by reducing the risk of accidents and injuries. In this section, we will explore these benefits in more detail.

Reducing the Risk of Accidents and Injuries

Loosened fasteners can pose significant safety risks, particularly in industries such as aviation and automotive racing where high speeds and extreme conditions are present. By using lock wire to prevent fastener loosening, businesses and organizations can reduce the risk of accidents and injuries, creating a safer and more secure work environment for their employees.

Improving Equipment Reliability and Performance

By preventing fastener loosening and failure, lock wire helps to improve the reliability and performance of machinery and equipment. This can lead to reduced downtime and maintenance costs, as well as increased productivity and profitability for businesses and organizations.

Compliance with Industry Standards and Regulations

Many industries have strict standards and regulations concerning workplace safety and equipment reliability. By using lock wire to secure critical fasteners, businesses and organizations can ensure that they are meeting these standards and complying with regulations, helping to avoid costly fines and legal issues.

Conclusion

Lock wire plays a crucial role in mitigating risk and ensuring workplace safety by keeping fasteners secure and preventing equipment failure. Proper installation and use of lock wire can help to improve equipment reliability and performance, reduce the risk of accidents and injuries, and ensure compliance with industry standards and regulations. By understanding the importance of lock wire and its various applications across different industries, businesses and organizations can create a safer and more secure work environment for their employees, while maximizing productivity and profitability.