When it comes to protecting your equipment, choosing the right lock wire is critical. Lock wire is a type of wire that is used to secure bolts, screws, and other fasteners in place to prevent them from loosening due to vibration, temperature changes, or other factors. In this article, we will explore the importance of lock wire and the factors that must be considered to choose the optimal lock wire for your equipment.

Understanding Lock Wire and Its Importance

Lock wire is an essential component of many industrial applications, including aerospace, automotive, and marine. It is often used in place of lock nuts, lock washers, and other conventional fasteners that rely on physical deformation to keep them in place. When used correctly, lock wire can provide greater protection against loosening, which can prevent costly breakdowns, accidents, and even catastrophic failures.

What is Lock Wire?

Lock wire, also known as safety wire or mechanics wire, is a type of wire that is made of steel or other high-strength metals. It is typically very thin, ranging from 0.020 to 0.032 inches in diameter, and is often coated with a layer of rust-resistant material to improve its durability and corrosion resistance.

Lock wire is commonly used in a variety of applications, including aircraft engines and landing gear, automotive engines and transmissions, marine engines and propellers, and industrial machinery. It is also used in safety critical applications such as brake systems, steering systems, and suspension systems.

Why is Lock Wire Essential for Equipment Protection?

The purpose of lock wire is to prevent fasteners from loosening due to vibration, temperature changes, or other factors. When a fastener becomes loose, it can cause other components to shift and wear unevenly, which can lead to premature failure of the equipment. In addition, loose components can pose a safety hazard to workers, especially in high-speed or high-impact environments.

For example, in aircraft engines, the use of lock wire is critical to ensure the safety of passengers and crew. The high speeds and forces involved in flight can cause fasteners to loosen, which can lead to catastrophic failure of critical components. By using lock wire, the risk of such failures is greatly reduced, ensuring the safety of everyone on board.

Common Applications of Lock Wire

Lock wire is commonly used in a variety of applications, including:

Aircraft Engines and Landing Gear: Lock wire is used to secure critical components in aircraft engines and landing gear, including bolts, nuts, and screws. This ensures that these components remain in place, even under extreme conditions.

Automotive Engines and Transmissions: Lock wire is used in automotive engines and transmissions to prevent fasteners from loosening due to vibration and other factors. This helps to prevent breakdowns and costly repairs.

Marine Engines and Propellers: Lock wire is used to secure fasteners in marine engines and propellers, which are exposed to harsh saltwater environments that can cause corrosion and other forms of damage.

Industrial Machinery: Lock wire is used in a wide range of industrial machinery, including pumps, compressors, and generators. It helps to ensure that critical components remain in place, even under heavy loads and extreme conditions.

Overall, lock wire is an essential component of many industrial applications, providing greater protection against loosening and helping to prevent costly breakdowns and accidents. By understanding the importance of lock wire and its common applications, you can ensure that your equipment remains safe and reliable, even in the most demanding environments.

Types of Lock Wire Materials

Lock wire is a type of wire that is used to secure bolts, nuts, and other fasteners to prevent them from loosening due to vibrations or other forces. There are several types of lock wire materials available, each with its own unique properties and applications.

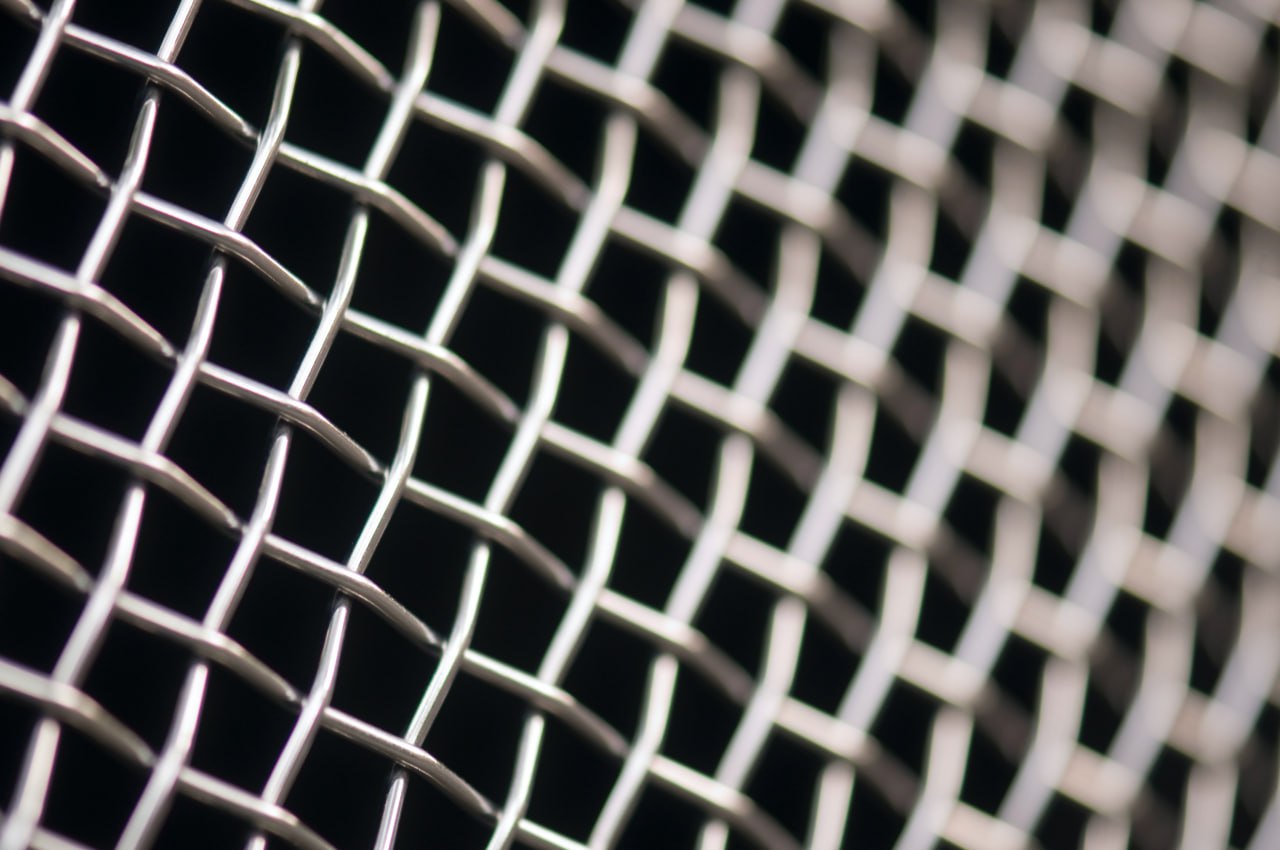

Stainless Steel Lock Wire

Stainless steel lock wire is the most commonly used type of lock wire due to its excellent corrosion resistance, strength, and durability. It is made from a type of steel that contains chromium, which gives it its corrosion-resistant properties. Stainless steel lock wire is ideal for use in applications where exposure to moisture, humidity, or saltwater is a concern.

Stainless steel lock wire is widely used in the aerospace, automotive, and marine industries. It is often used to secure critical components such as engine bolts, landing gear, and control cables. Stainless steel lock wire is also used in construction and industrial applications where safety is a concern.

Inconel Lock Wire

Inconel lock wire is a high-temperature alloy that is ideal for use in applications that require resistance to extreme heat, corrosion, or oxidation. It is made from a combination of nickel, chromium, and iron, which gives it its high-temperature properties. Inconel lock wire is often used in aerospace and industrial applications that involve exposure to high temperatures or harsh chemicals.

Inconel lock wire is commonly used to secure components in gas turbines, jet engines, and other high-temperature applications. It is also used in the chemical and petrochemical industries, where it is exposed to corrosive chemicals and high temperatures.

Monel Lock Wire

Monel lock wire is a nickel-copper alloy that is known for its excellent corrosion resistance and strength. It is made from a combination of nickel, copper, iron, and other trace elements, which gives it its unique properties. Monel lock wire is commonly used in marine and offshore applications due to its resistance to saltwater and other corrosive environments.

Monel lock wire is used to secure components in offshore oil rigs, ships, and other marine applications. It is also used in chemical processing plants and other environments where corrosion is a concern.

Copper Lock Wire

Copper lock wire is a soft, malleable wire that is ideal for use in non-critical applications such as wiring harnesses and electrical connections. It is made from pure copper, which gives it its excellent electrical conductivity. Copper lock wire is not suitable for use in high-stress or high-temperature environments.

Copper lock wire is commonly used in the electronics and telecommunications industries. It is used to secure electrical connections and to create wiring harnesses for electronic devices.

Factors to Consider When Choosing Lock Wire

Equipment Material Compatibility

One of the most important factors to consider when choosing lock wire is equipment material compatibility. Lock wire must be compatible with the material of the fastener it is securing to prevent galvanic corrosion and other types of corrosion. For example, stainless steel lock wire should be used with stainless steel fasteners, and copper lock wire should be used with copper fasteners.

It’s important to note that even if the lock wire is compatible with the fastener material, it may not be compatible with other materials in the equipment. For example, if the equipment has aluminum components, using copper lock wire may cause corrosion due to the dissimilar metals. In this case, it’s important to consult with a materials engineer to determine the best lock wire for the application.

Temperature Resistance

The temperature resistance of lock wire is another important factor to consider. Lock wire must be able to withstand the operating temperature of the equipment it is securing without becoming brittle or losing its strength. Inconel lock wire is often used in high-temperature applications, while stainless steel lock wire is suitable for moderate temperature ranges.

It’s important to consider not only the maximum operating temperature of the equipment, but also any temperature fluctuations that may occur. If the equipment experiences rapid temperature changes, the lock wire must be able to handle those changes without becoming damaged.

Corrosion Resistance

Lock wire must be able to withstand the corrosive environment it will be exposed to without becoming rusted or corroded. Corrosion-resistant coatings can help improve the durability and longevity of lock wire in harsh environments.

It’s important to consider the type of corrosion that the lock wire will be exposed to. For example, if the equipment will be exposed to saltwater, the lock wire must be able to withstand the corrosive effects of salt. In this case, stainless steel lock wire with a saltwater-resistant coating may be the best option.

Tensile Strength

The tensile strength of lock wire is an important consideration when selecting the appropriate wire for your application. The wire must be strong enough to resist stress and strain without breaking or becoming deformed. Stainless steel lock wire typically has higher tensile strength than copper or aluminum wire.

It’s important to consider not only the maximum load that the lock wire will be subjected to, but also any vibrations or shock loads that may occur. Lock wire that is too weak may break under these conditions, leading to equipment failure.

Ease of Installation and Removal

Finally, ease of installation and removal is an important factor to consider when selecting lock wire. Wire that is too thick or difficult to manipulate may be challenging to install, while wire that is too thin may be difficult to remove or replace.

It’s important to consider the accessibility of the fastener and the tools that will be used to install and remove the lock wire. In some cases, a thinner wire may be easier to work with, while in others a thicker wire may be necessary for added strength.

By considering all of these factors, you can select the best lock wire for your equipment and ensure that it will provide reliable and long-lasting performance.

Conclusion

Choosing the right lock wire is essential for optimal equipment protection. Consider factors such as equipment material compatibility, temperature resistance, corrosion resistance, tensile strength, and ease of installation and removal when selecting the appropriate wire for your application. By taking these factors into consideration, you can ensure that your equipment stays secure and protected against loosening, wear, and other types of damage.